Shop Inspection

Services

GIS is focused on technical inspection.

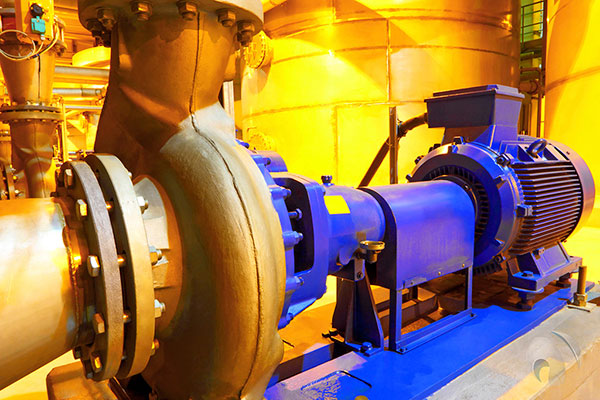

The most requested service is the inspection of mechanical and electrical equipment at workshop.

These assignments are carried out as residence, semi-residence or spot basis ("on call"), as per client’s requisition.

The scope can cover:

- Pre – Inspection Meetings (PIM)

- Expediting

- FAT Test (Factory Acceptance Test)

- Monitoring of ITP tests during fabrication (END, pressure tests, running tests)

- Visual inspection

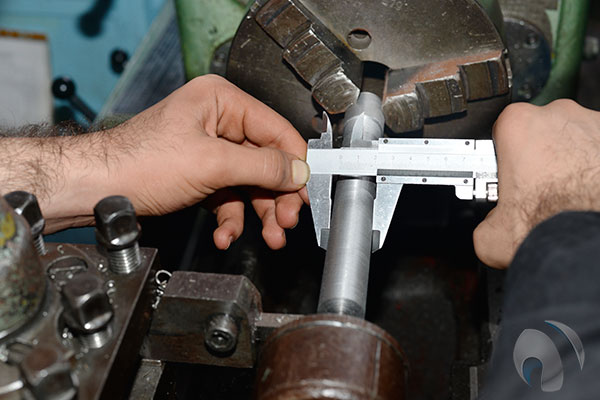

- Dimensional, Thickness measurements, and other tests

- Final inspection & Technical Assessment

- Documental review

- Among others

GIS comply with internal rigorous procedures with an approach to the excellence: meticulous work and well detailed reports are our distinctive.

These types of services are subjected to the tightly follow up of an ITP, which establishes the procedures, standards or specifications to comply for testing and defining the acceptance criteria.

GIS can develop ITP for our clients. This service is provided by our technical staff.

Using own inspectors Spain, France, Germany, Italy, Mexico, Chile or China; and a database with more than 2.500 inspectors all over the world; GIS consolidates as a global and reliable supplier. Its capacities and coverage are our main asset. For more information, please visit LOCATIONS

Second Party

This type of services is provided for Spanish and International Contractors such as Dragados, Duro Felgues, Intecsa Industrial, OHL Industrial, Sacyr Industrial, Sadyt, Drace, Tedagua, Acciona Infraestructuras, Aker Solutions, among others.

Third Party

GIS takes part as an independent Inspection Body, classified as 1st class by ISO 17020 Standards, meaning it acts as an independent part (Third Party Inspections). This type of service is provided for an EPC or Final client, public or private organizations, nationals as well as internationals.

Expediting

As per client’s petition, we expedite supplier in order to verify the following:

- Manufacturing status and stockfill

- Fabrication delays and cause

- Material and human resources in the shop